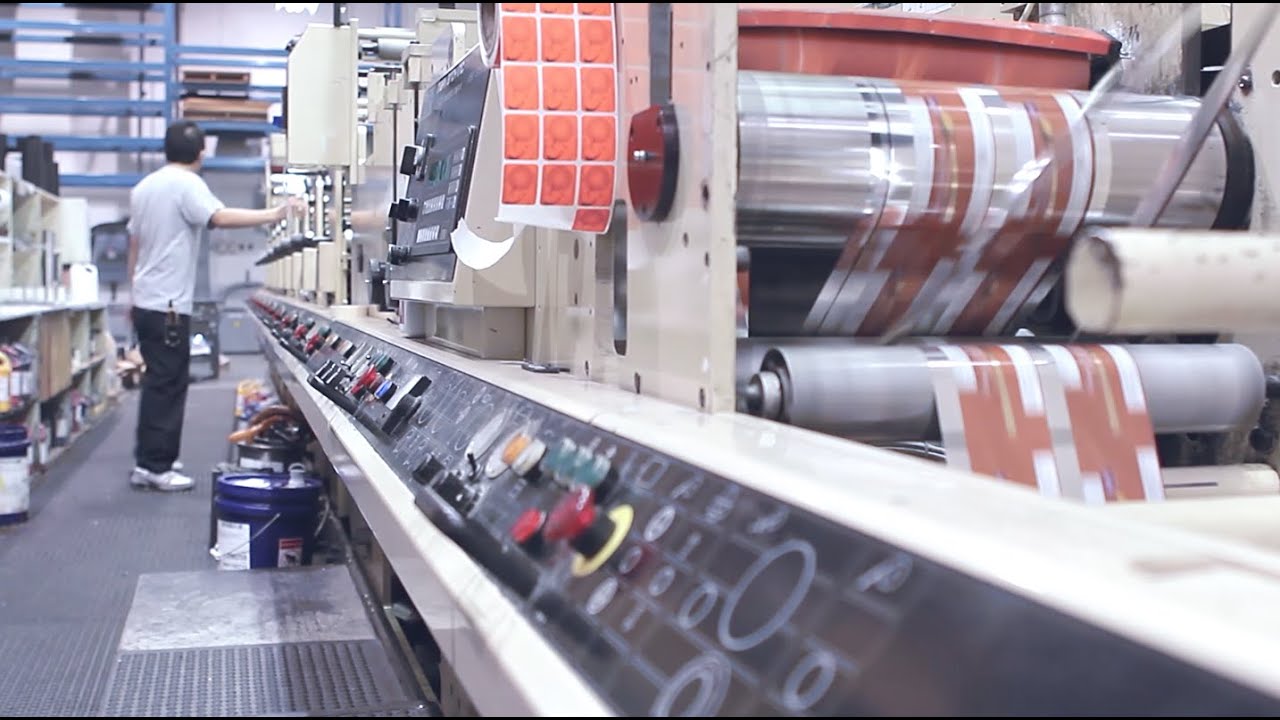

Pressure sensitive labels are a versatile and innovative solution for labeling products and packaging. These labels are designed to adhere to surfaces simply by applying pressure, eliminating the need for any heat activation or solvent-based adhesives. This technology allows for easy and efficient application, making it a popular choice for various industries. Whether you’re a small business owner or a large-scale manufacturer, pressure sensitive labels offer numerous advantages.

One of the key benefits is their adaptability to different surfaces. These labels can be applied to glass, plastic, metal, or even uneven textures with ease, ensuring a seamless and professional appearance. Additionally, pressure sensitive labels can withstand various environmental conditions, such as moisture, temperature changes, and exposure to sunlight, without losing their adhesive properties. This durability ensures that your labels remain intact and legible throughout the product’s lifespan.

Another advantage of pressure sensitive labels is their versatility in design and customization. With a wide range of materials, finishes, sizes, and shapes available, you can create labels that truly reflect your brand’s identity and catch the eye of potential customers. Whether you require vibrant colors, metallic accents, or a clear and minimalistic look, these labels can be tailored to meet your specific requirements.

In conclusion, pressure sensitive labels offer a practical, durable, and customizable labeling solution that adds value to your products and enhances your brand’s image. Their easy application process and versatility make them an ideal choice for businesses across various industries. So, whether you’re looking to label cosmetics, food products, electronics, or any other items, consider using pressure sensitive labels to elevate your packaging and captivate your target audience.

Pressure Sensitive Labels

| Property | Description |

|---|---|

| Pressure Activation | Pressure sensitive labels, also known as self-adhesive labels, are activated and adhere to surfaces under the application of light pressure. This unique characteristic sets them apart from other labeling options. |

| Adhesive Composition | The adhesive used in pressure sensitive labels is typically a tacky substance that enables adhesion to various surfaces, including plastic, glass, metal, and paper. This versatile adhesive composition ensures excellent bonding regardless of the substrate. |

| Conformability | One of the key advantages of pressure sensitive labels is their exceptional conformability. They conform easily to curved, irregular, or textured surfaces, providing a seamless and professional appearance. This capability makes them ideal for labeling products with unique shapes or uneven surfaces. |

| Durability | Pressure sensitive labels are designed to withstand various environmental conditions, including exposure to moisture, heat, cold, and UV radiation. This durability ensures that the labels maintain their adhesive properties and legibility, even in challenging settings. |

| Removability | While pressure sensitive labels offer excellent adhesion, they can also be easily removed without leaving behind residue or damaging the surface. This feature allows for efficient label changes or product rebranding without compromising the integrity of the labeled item. |

| Customizability | Pressure sensitive labels offer a wide range of customization options in terms of size, shape, color, and design. This flexibility allows businesses to create labels that align precisely with their branding guidelines, enhancing product visibility and brand recognition. |

In summary, pressure sensitive labels are versatile labeling solutions that activate through the application of light pressure. Their unique adhesive composition enables adhesion to various surfaces, while their exceptional conformability ensures a seamless application on curved or irregular objects. With outstanding durability and removability, these labels can withstand harsh environments and allow for effortless label changes. Furthermore, their customizability empowers businesses to create visually appealing labels that enhance brand recognition.

“Revolutionizing Product Packaging: Unveiling the Cutting-Edge Pressure Sensitive Labels”

What Are Pressure Sensitive Labels?

Pressure sensitive labels are a popular type of label used in various industries for packaging and product labeling purposes. These labels are made from a combination of materials, including a facestock (the visible part of the label), an adhesive layer, and a release liner that protects the adhesive until the label is applied.

The Components of Pressure Sensitive Labels

Facestock: The facestock is the part of the label that contains the printed information or design. It can be made from a variety of materials, such as paper, film, or even metalized materials. The choice of facestock depends on factors such as the application, durability requirements, and desired aesthetic appeal.

Adhesive Layer: The adhesive layer is what allows the label to stick to various surfaces. Pressure sensitive labels use a special type of adhesive that is activated by pressure, hence the name. This adhesive is designed to create an instant bond when pressure is applied during label application.

Release Liner: The release liner is a backing material that protects the adhesive until the label is ready to be applied. It is typically made from silicone-coated paper or film, which allows for easy release of the label from the liner. Once the label is applied, the liner is removed and discarded.

The Advantages of Pressure Sensitive Labels

Versatility: Pressure sensitive labels are highly versatile and can be used on a wide range of surfaces, including glass, plastic, metal, and paper. This makes them suitable for various applications, from food and beverage packaging to industrial labeling.

Easy Application: Applying pressure sensitive labels is a simple process that can be done manually or with the help of automated labeling machines. The adhesive layer allows for easy and quick application, without the need for additional tools or equipment.

Durability: Pressure sensitive labels are designed to withstand various environmental conditions, such as temperature changes, moisture, and UV exposure. This makes them highly durable and ensures that the labels remain intact and legible throughout the product’s lifecycle.

The Different Types of Pressure Sensitive Labels

Permanent Labels: Permanent pressure sensitive labels are designed to adhere securely to the surface they are applied to and are difficult to remove without damaging the label or the surface. They are commonly used for product branding or labeling where long-term adhesion is required.

Removable Labels: Removable pressure sensitive labels are designed to be easily removed without leaving any residue or damaging the surface. They are commonly used for temporary promotions, labeling rental equipment, or any situation where the label needs to be easily removed after use.

Repositionable Labels: Repositionable pressure sensitive labels offer a unique feature where they can be applied, removed, and reapplied multiple times without losing their adhesive properties. This makes them ideal for applications where frequent repositioning is required, such as labeling reusable containers or organizing inventory.

The Applications of Pressure Sensitive Labels

Food and Beverage: Pressure sensitive labels are widely used in the food and beverage industry for product labeling, ingredient information, and branding purposes. They are capable of withstanding refrigeration, moisture, and handling, ensuring that the labels remain intact and legible throughout the product’s shelf life.

Pharmaceuticals: Pressure sensitive labels play a crucial role in the pharmaceutical industry by providing important information regarding dosage instructions, expiration dates, and safety warnings. These labels must adhere securely to various packaging materials, ensuring the integrity and readability of the information.

Retail Packaging: Pressure sensitive labels are commonly used in retail packaging to display product information, barcodes, and pricing. They offer a cost-effective and efficient solution for labeling products of various shapes and sizes, enhancing brand visibility, and facilitating inventory management.

Industrial Labeling: Pressure sensitive labels find extensive use in industrial environments for labeling equipment, machinery, and safety signage. These labels often need to withstand harsh conditions, such as exposure to chemicals, extreme temperatures, and outdoor elements, while remaining legible and intact.

Conclusion

Pressure sensitive labels are a versatile and practical labeling solution used in various industries. They offer easy application, durability, and a wide range of customization options. Whether it’s for product branding, information labeling, or inventory management, pressure sensitive labels provide a reliable and efficient way to communicate important information and enhance the overall product presentation.

What are Pressure Sensitive Labels

- Pressure sensitive labels are adhesive labels that adhere to surfaces when pressure is applied.

- They are made from thin, flexible materials such as paper, film, or synthetic materials.

- These labels are designed to stick to a variety of surfaces including glass, plastic, metal, and cardboard.

- They are commonly used in industries such as food and beverage, pharmaceuticals, cosmetics, and retail.

- Pressure sensitive labels can be printed with various designs, texts, and graphics to meet specific branding or informational needs.

- They are easy to apply and do not require additional heat, water, or solvents for activation.

- These labels can be easily removed without leaving behind any residue or damage to the surface.

- Pressure sensitive labels are available in different formats including rolls, sheets, or individual pieces.

- They offer excellent durability and resistance to moisture, UV light, chemicals, and abrasion.

- They provide a cost-effective labeling solution for small and large-scale applications.